Vevor Hat Heat Press Reviews – Pros, Cons, and Comparisons

Introduction to Vevor Hat Heat Press

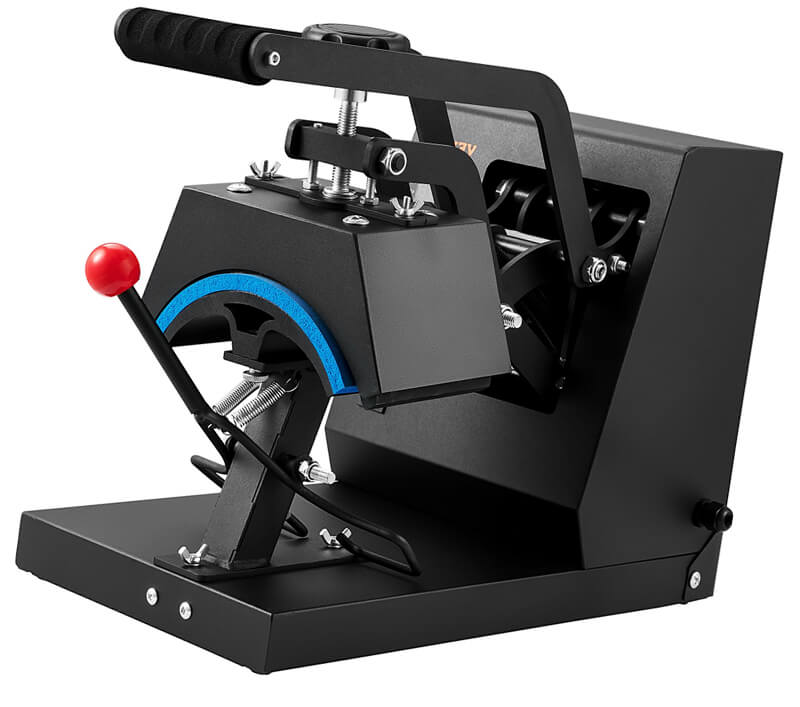

Vevor makes the Vevor Hat Heat Press. Its purpose is to transfer detailed designs onto hats. This adaptable machine accommodates different hat styles and sizes, ideal for both personal and business purposes.

With adjustable temperature and pressure settings, this device allows extensive customization to accommodate different materials and designs, ensuring top-notch results. Its user-friendly interface is accessible for both beginners and experienced users, and its durable construction guarantees longevity.

Vevor, renowned for its reliable and efficient heat press machines, maintains its respected reputation with this innovative product. It offers a straightforward and effective way to imprint graphics on hats, guaranteeing each project shines with professional quality.

Quick Glance at Vevor Hat Heat Press Specifications

| Feature | Specification |

|---|---|

| Quality | High-quality, durable, stable |

| Plate Material | Die-casting aluminum |

| Service Life | 12,000 hours |

| Design | Exclusive, ergonomic, user-friendly |

| Application | Wide; including advertising, gifts, promotional activities |

| Platen Size | 5.5 x 3.5″ / 9 x 14 cm (Curved Element) |

| Temperature Range | 0 – 399 °C / 0 – 750 °F |

| Timer Control | 0-999 s |

| Wattage | 400 W |

| Power Input | 110 V |

| Product Size | 9 x 17.1 x 12.2 in / 23.5 x 43.5 x 31 cm |

| Weight | 24 lbs / 10.9 kg |

Additional Information:

- Precise Heat Effect: Prevents twisting and torque compared to single-arm machines.

- Wide Application: Capable of printing any colorful marks, portrait photos, landscape patterns, and personalized patterns, especially on hats/caps.

- Suitable for: Making various gifts and souvenirs, colorful marks, characters, and patterns on the hat.

- Usability: Easy to use with a user-friendly clamshell, easy cleaning due to Teflon-coated heating platen.

Vevor Hat Heat Press: Remarkable Quality and Build

The Vevor Hat Heat Press is a standout in the heat press machine market. Customers highly regard the Vevor Hat Heat Press in the heat press machine market. It stands out due to its exceptional quality, sturdy construction, stylish design, and long-lasting durability. These features give it a significant edge over its competitors.

Durable, Stable Construction, and Elegant Design

Crafted with top-tier materials, the Vevor Hat Heat Press exhibits exceptional durability and stability for rigorous commercial use. Its sleek design and superior craftsmanship improve functionality and user experience. The ergonomic foam parallel arm handle minimizes obstructions, setting it apart from less efficient models.

Enhanced Performance with Cutting-Edge Features

Equipped with an accurate digital controller and an automatic time regulator, this machine epitomizes precision. It auto-stops heating and alerts users upon reaching preset time and temperature, effectively averting damage and emphasizing user safety.

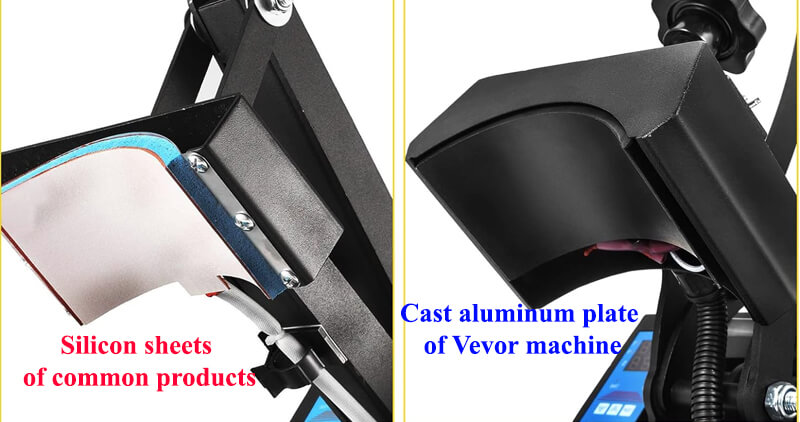

Uniquely, the press uses a die-casting aluminum plate, outperforming competitors with standard silicone heating pads. This results in a notable 12,000-hour lifespan – a major advancement in durability.

Versatile Design for Diverse Applications

The Vevor Hat Heat Press is great for printing designs on hats and caps, ensuring excellent results with its curved component. Intelligent control and integrated displays make setting adjustments a breeze, enhancing control precision.

This press is great for putting images and text on hats. It’s popular for ads, events, and making personalized items.

Can I use heat press on hat?

Yes, you can use a heat press on hats. However, we recommend using a specialized cap heat press designed for hats to achieve optimal results and prevent damage. Always ensure you’re following the hat material’s specific guidelines for temperature settings and press duration.

Quality Advantage Over Competitors

The Vevor Hat Heat Press commands attention with its enhanced lifespan, innovative design, superior performance, and robust build. A Teflon-coated heating platen helps with sticking, makes cleaning easier, and makes printing more stable. This makes it better than competitors.

Unique Features and Specifications of Vevor Hat Heat Press

Advantage of Die-Casting Aluminum Plate in Vevor Hat Heat Press

The Vevor Hat Heat Press is more durable and reliable than other presses. This is because it has a die-casting aluminum plate instead of standard silicone pads. This innovation enables a notable 12,000-hour service life.

Known for superior heat distribution, aluminum ensures uniform transfers and eliminates hotspots, which are crucial for high-quality results on intricate designs. It also supports rapid heating and cooling, fostering energy efficiency and cutting operational costs. Additionally, the robust nature of aluminum withstands deformation and corrosion, preserving the plate’s integrity even under extensive use, in line with the machine’s refined design.

Exceptional Precision with Digital Controller and Automatic Time Regulator

The Vevor Hat Heat Press has a smart controller and timer for precise and reliable results every time. Users can accurately control temperature and time, minimizing mistakes and ensuring optimal conditions for successful outcomes and safe handling of materials.

Furthermore, the time regulator improves the user experience by halting the heat and sounding an alarm under preset conditions. This feature protects against damage and overheating, providing extra security and convenience.

What is the max temperature on the Vevor heat press?

The maximum temperature for a Vevor heat press machine varies depending on the specific model you have. Most Vevor heat presses have a maximum temperature of 570°F (299°C). However, it is important to check the manual or product specifications for your specific model to determine the exact maximum temperature. Always follow the manufacturer’s recommendations to ensure safety and product longevity.

Exclusive and User-Friendly Design Elements of Vevor Hat Heat Press

Featuring a distinctive and user-centric design, the Vevor Hat Heat Press prioritizes convenience and ease of operation. Its engineered curved components are adaptable to various hat types, ensuring outstanding printing results. Meanwhile, the ergonomic foam parallel arm handle stands out from conventional designs, increasing comfort and minimizing obstructions.

The machine boasts a practical clamshell design, promoting both user-friendliness and energy efficiency. The integrated intelligent control facilitates effortless setting adjustments. The heating platen is coated with Teflon to prevent sticking and make cleaning easy. This ensures a smooth and reliable heat-pressing experience for different uses.

How do you use a Vevor hat heat press attachment?

To use a Vevor hat heat press attachment, follow the steps in the user manual for your specific model. Here’s a general guide on how to use a Vevor hat heat press attachment:

1. Preparation:

- First, ensure the machine is off before you begin.

- Attach the hat press attachment by typically removing the existing platen and replacing it with the hat piece.

2. Power and Settings:

- Next, power on the machine.

- Wondering what temperature do you heat press a hat? Generally, hat temperatures hover between 280°F to 320°F (137°C to 160°C), but always check the transfer paper’s guidelines.

- Wait for the machine to reach the set temperature.

3. Placement:

- Open the heat press and meticulously slide the hat onto the curved part. It should lay flat and wrinkle-free.

- Then, place your graphic transfer in the desired spot on the hat.

4. Pressing:

- Gently close the heat press.

- When the timer ends, the machine will typically signal you – either with a beep or another alert.

- Carefully lift the press to finish this step.

5. Cooling and Finishing:

- Swiftly take the hat off the attachment.

- When using heat transfer vinyl on hats, wait until the hat cools a bit before peeling off the transfer’s carrier sheet for the best results.

- For other transfer types, adhere to the manufacturer’s removal instructions.

6. Safety and Maintenance:

- Remember, the machine gets extremely hot; handle it with care.

- After usage, give it time to cool.

- Lastly, consistently clean the attachment to prevent any residue from accumulating.

Efficiency and Safety: A Closer Look at Vevor Hat Heat Press’s Performance Features

The Vevor Hat Heat Press expertly balances efficiency and safety with its well-engineered features, guaranteeing optimal performance and user protection. It gives consistent printing results with its accurate digital controller and automatic time regulator. This ensures even heat distribution and protects against material overexposure, important for good transfers.

The machine improves safety by automatically stopping and sounding an alarm. It also has a protector to prevent voltage-related dangers. Its ergonomic and user-friendly design minimizes user strain, rendering the machine apt for extended use.

The Vevor Hat Heat Press is a reliable choice. It ensures safe and efficient operations. It also offers high-quality results. Additionally, it is user-friendly.

Pros and Cons of Using Vevor Hat Heat Press

Before using the Vevor Hat Heat Press machine, it is important to assess its pros and cons. This will help you determine if it meets your needs.

Pros

- Easy to use: The Vevor hat press has simple controls, making it easier for beginners to learn the heat press process.

- Quality: Renowned for delivering consistent heat and pressure, this machine sets the standard for high-quality heat transfers.

- Versatility: Demonstrating versatility, the machine accommodates a variety of applications, including transferring designs onto hats, caps, and other curved surfaces.

- Small design: This press is great for small spaces and is easy to move and store when not being used.

- Vevor’s products are affordable. They are suitable for both small business owners and hobbyists. This makes them accessible to a wide range of users.

- Adjustability: The machine boasts straightforward temperature and time adjustments for added convenience.

- The Vevor hat heat press is known for its strong construction, lasting through regular use without much damage.

Cons

- Learning Curve: New heat press users may need time to learn the best temperature and pressure settings for different materials.

- Only for hats: This machine is not good for flat or big surfaces, so it may not work for some people.

- Size Limitations: The pressing area may not accommodate larger designs or bigger hat sizes, posing a restriction for certain projects.

- Some users have reported problems with product quality and manufacturing defects, causing uneven heat distribution and other operational issues.

- Vevor’s hat press lacks advanced features like touchscreen controls or programmable settings, unlike its high-end counterparts.

Performance and User Experience with Vevor Hat Heat Press

Assessing Vevor Hat Heat Press’s Premium Transfer Quality & User-Friendly Design

The Vevor Hat Heat Press is popular because of its great transfer quality and easy-to-use design. The digital controller and time regulator ensure consistent, high-quality prints for different uses, guaranteeing unmatched transfer quality.

A die-casting aluminum plate ensures even heat, which is vital for perfect transfers. The user-centric design features an ergonomic foam parallel arm handle and a clamshell body. These elements reduce strain and increase comfort during extended use. Integrated temperature and time controls on a single display make setting adjustments intuitive, significantly enhancing the user experience.

Moreover, a Teflon-coated platen tackles adhesion issues, prevents burns, and eases cleaning, ensuring a reliable printing process. Safety features, such as an alarm and automatic heating stop, protect materials and users, making the machine more reliable.

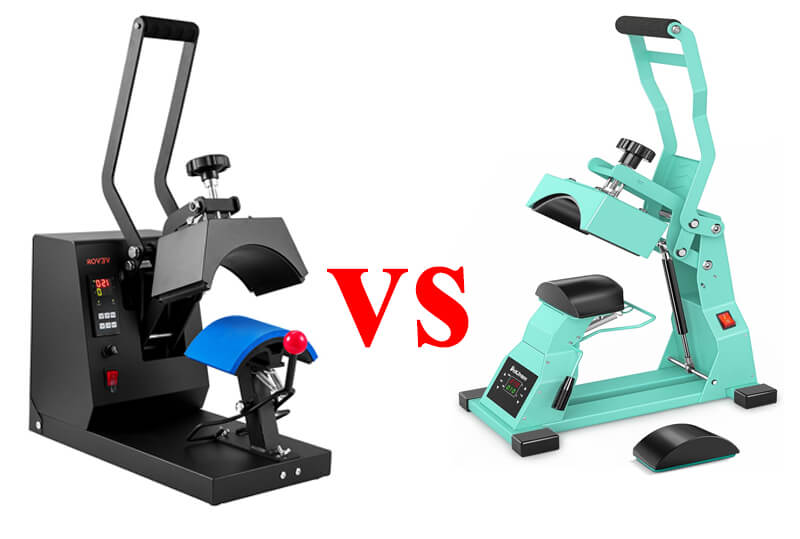

Comparative Analysis: Vevor Hat Heat Press vs Single-Arm Machines

The Vevor Hat Heat Press offers notable advantages over single-arm machines. It provides enhanced stability, precision, and user experience through its clamshell design, addressing common operational issues.

The machine features an accurate digital controller and automatic timer, ensuring consistent transfers. All settings are displayed on one screen, simplifying the user interface.

Furthermore, it includes additional safety features such as an automatic stop and alarm. The press is versatile, suitable for various hat types, and boasts an impressive 12,000-hour service life.

This longevity surpasses the maintenance needs of competitors. In summary, the advanced design and user-friendly features of Vevor make it a top choice for heat-pressing applications.

Vevor Hat Heat Press: A Versatile Tool with a Wide Range of Applications

The Vevor Hat Heat Press is a versatile tool. It can be used for many things such as advertising, making gifts, promotions, and more.

Delving into Vevor Hat Heat Press’s Diverse Applications in Advertising & Gifts

The Vevor Hat Heat Press stands as a versatile and essential tool, finding extensive applications in advertising and personalized gift creation. It facilitates the transfer of various designs onto hats, enabling the production of custom items for a multitude of purposes. This feature makes it highly valuable for both businesses and individuals.

In the realm of advertising, this machine plays a crucial role in crafting branded promotional items, thereby enhancing brand visibility. For personal use, it paves the way for the creation of unique and sentimental gifts. Thanks to its user-friendly and efficient design, the machine assures seamless operation and high-quality results. Consequently, it emerges as an invaluable tool for extensive customization in hat design.

Comparison: Vevor Hat Heat Press vs. Other Leading Brands

In the world of hat heat presses, choosing the right machine for your needs can be challenging. Here’s a streamlined comparison between the Vevor Hat Heat Press and its competitors.

1. Vevor Hat Heat Press:

- Material: Durable Aluminum and Alloy Steel.

- Features: A remarkable 12,000-hour service life owing to its die-casting aluminum plate. It boasts a precise digital and automatic time controller, making the pressing process seamless. Its ergonomic foam parallel arm handle sets it apart, optimizing comfort during use.

- Best for: Those seeking longevity and precision.

2. SmarketBuy Heat Press:

- Material: Sturdy Iron.

- Features: A versatile 5-in-1 design, with a teflon-coated heating plate ensuring even heat distribution. Its 360-degree rotation feature minimizes accidents and enhances user experience.

- Best for: Multi-product entrepreneurs needing versatility.

3. Hat Heat Press with Interchangeable Platens:

- Features: Two interchangeable platens allow for pressing on various cap types. The silicone lower platen reduces marking, and its compact design makes it space-efficient.

- Best for Businesses or individuals working with diverse cap styles.

4. PNKKODW Digital Baseball Cap Heat Press:

- Material: Aluminum and Alloy Steel.

- Features: The clamshell design ensures user safety. It comes with a Teflon-coated element and a digital timer, guaranteeing precision in every press.

- Best for: Daily business and home use, offering a balance between design and functionality.

Each heat press offers unique benefits. Vevor is durable, SmarketBuy is versatile, Interchangeable Platens is customizable, and PNKKODW is user-friendly. Your choice should align with your pressing needs and frequency of use.

Final Thoughts

The VEVOR Heat Press stands out as a top choice for hat-making endeavors. It boasts rapid heating, a user-friendly handle, and a practical clamshell design ensuring even heat distribution. By simply being mindful of potential temperature variations and clearance concerns, users can confidently rely on this device for superb outcomes.

Overall impression

The VEVOR Hat Press stands out as an exemplary heat press. Made with premium materials, it ensures swift and professional ink or vinyl transfers onto hats.

Many customers note its quick heating capability, coupled with precise temperature and timer controls. This ensures top-notch printing results consistently.

Moreover, its user-friendly features have garnered praise, enhancing its overall appeal. Numerous glowing testimonials emphasize its remarkable efficiency, especially considering its affordable price point compared to rival products.

Recommendation

For those prioritizing quality and versatility, the Vevor Hat Heat Press is a top choice. It stands out with its dependable heat, pressure, and timer settings, ensuring top-tier results for varied uses.

Its trio of platen sizes means versatility in handling diverse hat types. Coupled with stellar heating prowess, it guarantees perfectly pressed hats every time through exact temperature management.

Many customers vouch for its precision across fabric types. Plus, when stacked against similar products from rivals, the Vevor offers unmatched value in terms of both functionality and performance.

Conclusion

The VEVOR Hat Heat Press stands out as an efficient, feature-packed device, perfect for pressing logos onto hats. Its clamshell design, coupled with a curved element, ensures uniform heat distribution, resulting in top-notch output swiftly.

Its user-friendly features like the adjustable pressure knob, solid base, and easy-grip handle make it a breeze for beginners. Many users highlight its rapid heating and consistent temperature maintenance.

One user did mention a clearance issue when moving the press to the side. Still, this seems more like a unique instance rather than a widespread problem.

In summary, this machine excels in production lines, combining swift processes with quality. It’s an ideal pick for those into personalized manufacturing or DIY enthusiasts seeking cost-effective, high-quality outcomes.

FAQs

1. How do you heat press a hat with vinyl?

- Choose the appropriate vinyl for your hat.

- Cut and weed your design from the vinyl.

- Position the hat on the heat press, ensuring it’s flat and wrinkle-free.

- Place the vinyl design on the hat in the desired position.

- Apply heat according to the vinyl manufacturer’s recommendations, usually around 280°F – 320°F (137°C – 160°C) for about 10-15 seconds.

- Allow it to cool slightly and then peel off the carrier sheet.

2. What kind of vinyl is best for hats?

People often suggest using stretchy heat transfer vinyl for hats because of their curved shape and ability to flex.

3. Can you heat press vinyl on hats?

Yes, you can heat press vinyl onto hats. It’s essential to use the right type of vinyl and ensure that both the hat’s material and the vinyl are compatible. A curved heat press or cap press is ideal for this purpose.

4. What is the best temperature and time for a heat press?

The variation depends on the type of material and vinyl being used. Generally, for heat transfer vinyl, temperatures range from 280°F to 320°F (137°C to 160°C). The pressing time typically ranges from 10-15 seconds. However, always refer to the manufacturer’s guidelines for the specific vinyl and material you’re using.