A Comprehensive Guide: Can You Sublimate on Acrylic Beanies?

Seeking a method to infuse your acrylic beanie with vivid, enduring hues? You’re in good company! We’ve delved into extensive research to compile this comprehensive guide, aiming to empower you with the knowledge to make well-informed choices regarding sublimation on acrylic beanies.

In this article, we’ll explore the diverse properties of materials, guide you through the correct sublimation processes, and offer valuable tips for achieving impeccable prints. Additionally, we’ll address any common queries you might have, ensuring you’re well-equipped to craft stunning personalized designs. Let’s dive in!

Key Takeaways

- Acrylic fabric is a great choice for sublimation printing due to its heat resistance, shrink resistance, and raw color manipulation ability.

- It is important to consider the advantages and disadvantages of sublimating onto acrylic beanies such as durability, fade resistance, an unnoticeable finish, and unpredictable outcomes.

- When using the dye-sublimation process on acrylic beanies there are multiple steps involved including pre-dressing the beanie, cutting out design, aligning & pressing as well as cooling off period after completion.

- Design considerations when creating artwork include placement (front or side of beany’), size (print must not exceed brim area), and material type (specialized software needed).

Understanding Acrylic Material

Acrylic fabric is known for its heat resistance, shrink resistance, and raw color options which make it an ideal candidate for a variety of customization processes.

Why are beanies made of acrylic?

Acrylic beanies have surged in popularity, blending affordability, durability, and convenience for consumers. Unlike wool or cotton, acrylic emerges as a budget-friendly option, given its cost-effective production. This material is renowned for its durability, expertly resisting wear, tear, and sunlight—essential qualities for everyday items like beanies.

Acrylic boasts notable insulating properties, making it a warm companion for winter wear. It also stands as a hypoallergenic alternative, a significant benefit for those allergic to natural fibers. This material is known for its ability to hold dye effectively, ensuring colors remain vibrant over time. Furthermore, its resistance to moths and chemicals sets it apart from wool, simplifying maintenance.

In addition, the lightweight nature of acrylic enhances the comfort of the beanie, while its ability to retain shape post-washing heightens its appeal. For consumers seeking non-animal products, acrylic shines as a commendable vegan alternative to wool. With these attributes, acrylic beanies continue to be a go-to choice for many, balancing style, comfort, and practicality.

Heat resistance

Renowned for its thermal resistance, acrylic material stands as an exemplary choice for sublimation printing, particularly on beanies. With a significantly high melting point, acrylic can endure more heat than most fabrics, safeguarding the fibers and preserving color integrity.

Notably, cast acrylic boasts a higher melting point and superior heat resistance compared to its counterpart, extruded acrylic. This characteristic implies a reduced risk of fabric damage when using sublimation dyes on apparel made with cast acrylic. The dye forms a permanent bond, as the fabric experiences minimal deformation during heating.

Hence, when employing dye-sublimation printing techniques to design and customize acrylic beanies, it’s advisable to opt for cast acrylic. This preference helps to avoid the potential damage that other fabrics, like cotton or synthetics, might incur due to excessive heat during transfer processes. By choosing wisely, you ensure the creation of a high-quality and resilient customized acrylic beanie.

Shrink resistance

Acrylic fabric stands out as a prime choice for apparel applications such as beanies, owing to its notable heat and shrink-resistant properties. The unique composition of acrylic grants it thermal stability, ensuring the fabric maintains its form even when subjected to the high temperatures involved in sublimation printing.

Furthermore, this distinctive property positions acrylic as the go-to material for crafting durable, long-lasting prints. Such prints maintain their vibrancy, resisting fading or distortion over time. The blend of acrylic’s resilient nature and its soft texture elevates its desirability, extending its use beyond apparel to sublimation-friendly items like keychain blanks and photo panel blanks. This versatility allows clients to imbue these items with personalized, trendsetting designs through advanced dye-sublimation technology, enhancing their aesthetic appeal.

Raw color

Grasping the nature of acrylic material is pivotal in achieving successful sublimation prints on beanies. The concept of raw color plays a significant role; it involves adjusting the hues, shades, and tones of materials to craft intriguing pieces of art.

Acrylic possesses a unique blend of properties making it exceptionally suitable for such manipulations. Its heat resistance facilitates multiple layering without the risks of warping or scorching, while its shrink-resistant nature ensures the fabric remains undistorted and does not shrink during the drying time of the paints.

Moreover, acrylic’s inherent pigmentation allows for a wider scope of creative exploration, thanks to its compatibility with a diverse spectrum of colors and theories. To realize effective printing through sublimation, a comprehensive understanding of how these foundational characteristics interplay is essential. This knowledge enables artists to adeptly manipulate color saturation layers to generate the envisioned visual effects efficiently.

Advantages and Disadvantages

Sublimation printing on acrylic beanies has its own set of benefits and drawbacks. While acrylic materials provide excellent durability, fade resistance, and an unnoticeable finish, they can also pose challenges such as unpredictable printing outcomes and special requirements for heat press settings. Now, let’s break down the advantages and disadvantages:

| Advantages | Disadvantages |

|---|---|

| Durability: Acrylic is renowned for its durability, making it a preferred choice for beanies. | Unpredictable Outcomes: Sublimation printing can be unpredictable, making it difficult to achieve consistent results |

| Fade Resistance: Acrylic materials retain vibrant colors due to their resistance to fading | Heat Settings: Specific heat settings are required for optimal results when sublimating on acrylic beanies |

| Subtle Finish: Sublimation printing yields a seamless and smooth design on acrylic beanies | Custom Designs: While acrylic sublimation paint can create unique designs, the process is more intricate and lengthy compared to standard sublimation printing |

| Dye Absorption: Acrylic fabrics can imbibe sublimation dyes, resulting in bright and enduring designs | Since acrylic fabric is synthetic, it tends to attract dust and bacteria, leading to unpleasant odors if worn for long durations |

Taking these factors into account is vital when selecting the optimum material for your printing endeavors. Acrylic beanies offer a robust and vivid canvas for sublimation printing, breathing life into your imaginative concepts. Nonetheless, it’s important to be mindful of the specific considerations and potential challenges associated with this distinctive material. Balancing creativity with material understanding can lead to remarkable and enduring results.

Sublimation Printing Process on Acrylic Beanies

Learn how to get started with customizing beanies using the sublimation printing process and uncover the tips for successful results! Interested in customizing hats? Discover How to Put Vinyl on a Hat with an Iron for more insights!

Can you do sublimation on hats?

Yes, you can use sublimation printing on hats, specifically those made of polyester or polyester blends, as this material bonds best with sublimation ink. It’s most effective on white or light-colored fabrics since the original color of the fabric can affect the final result. The process can be challenging on curved surfaces like hats, but special hat presses are available to address this. Caution is also necessary to avoid damaging hats with plastic components due to the high heat used in sublimation. Overall, careful planning of the design and printing process is essential, as sublimation is a permanent process.

Does sublimation work on acrylic?

Sublimation on acrylic is possible, but it requires a specialized approach to guarantee success. The acrylic surface necessitates a polyester-based coating to ensure the dye bonds effectively with the acrylic polymer; standard uncoated acrylic falls short. Thankfully, many craft and fabrication suppliers provide pre-coated acrylic sheets specifically designed for sublimation, adding to user convenience.

In the sublimation process, these sheets, paired with a design on transfer paper, are subjected to high temperatures, typically around 400°F or higher, within a heat press. This exposure to heat transforms the dye into gas, enabling it to meld into the acrylic. The outcome is a vibrant, integrated, and enduring design, resistant to both scratching and fading—a level of durability that direct printing on acrylic struggles to match.

Employing this technique, one can achieve high-quality, full-color photographic designs on acrylic, leading to the creation of vivid and long-lasting artworks. This method, with its distinct steps and attention to detail, ensures that sublimation on acrylic results in visually striking and durable pieces.

Steps involved in the sublimation process

Embarking on the sublimation process involves several key steps to ensure the final product is vibrant and long-lasting:

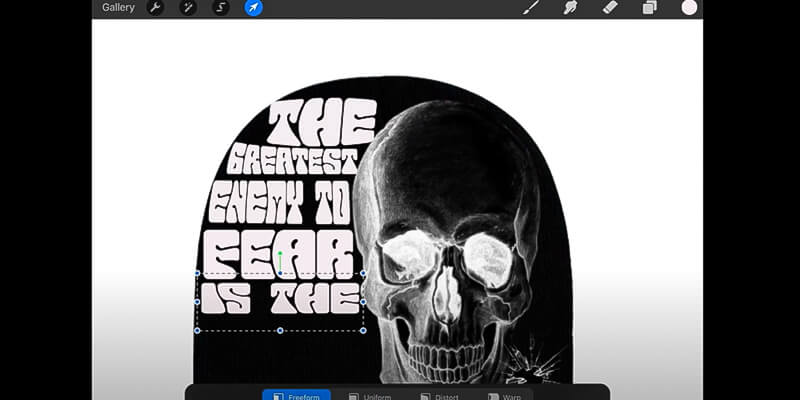

1. Design Creation:

Begin by crafting a design either from scratch or by utilizing specialized software. The design is then printed onto sublimation paper.

2. Preparation of Beanie:

Pre-dress the acrylic beanie by cleaning it with isopropyl alcohol to ensure an even surface for the design. This step is crucial for optimal adhesion of the design.

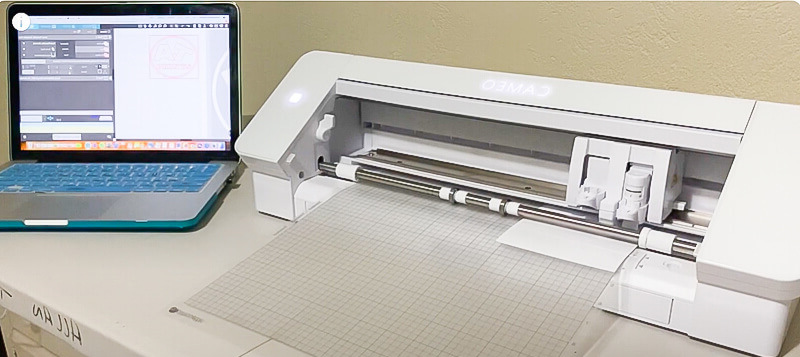

3. Cutting Out Design:

Carefully cut out the printed design that has been transferred onto the sublimation paper, ensuring no border or margin is left surrounding it.

4. Alignment and Placement:

Meticulously align and place the cut-out design onto the acrylic material. This step can be executed manually or with the aid of heat-pressing equipment such as temperature-controlled table presses and cap frames, ensuring precision at temperatures exceeding 400°F (204°C).

5. Transfer Press Setup:

Once the design is correctly positioned, set up your transfer press. It is vital to monitor temperatures accurately throughout the pressing sessions, as different materials may necessitate varying heat settings and durations depending on their thickness and other properties.

6. Pressing:

Close the heat press and apply pressure. Keep the pressure and heat applied for a specified time, usually around 60 seconds. It is important to ensure uniform pressure and temperature to avoid inconsistencies in the transferred image.

7. Layering and Colors (Optional):

If the artwork incorporates multiple colors, peel away each color layer individually after each pressing session and repeat steps 4 and 5 until the desired result is achieved. This method offers artists/designers increased flexibility for complex creations. Alternatively, a single large piece of sublimated polyester fabric can be placed over the entire work area instead of multiple separate layers, simplifying the preparation process and allowing for intricate designs, provided the pattern and layouts have been pre-determined in computer visuals before printing.

8. Cooling and Final Inspection:

After pressing is complete, allow the item to cool and remove any residual transfer paper or coatings. Inspect the final product to ensure the design is correctly transferred and vibrant.

Design considerations

Sublimating on acrylic beanies demands a firm grasp of essential design principles. For maximum impact, consider the placement of your designs. Ideally, images should sit towards the front or side of a beanie, ensuring higher visibility compared to positioning them at the back.

Moreover, size is pivotal in achieving the desired outcomes in sublimation printing on acrylic hats. An image that mistakenly surpasses the boundary set by the hat’s brim may result in a portion of the design being obscured or lost.

In addition, employing specialized software is vital when crafting designs for sublimation. Utilizing materials such as vector EPS files can yield superior results when applying the sublimation technique to acrylic beanies.

Heat transfer vinyl (HTV), due to its unique material composition, is incompatible with resin-coated paper. Hence, the use of specialized design software becomes indispensable for realizing the envisioned results. If you’re considering using heat transfer vinyl, it’s crucial to select the right type. Discover more about applying Heat Transfer Vinyl on Hats to ensure a flawless customization process.

Each of these considerations plays an integral role in ensuring the success of sublimating on acrylic beanies, allowing for designs that are not only visually appealing but also enduring.

Preparing the acrylic beanie for sublimation

Preparing the acrylic beanie for sublimation is a pivotal step in achieving the desired results. Selecting the right acrylic blank is essential, ensuring it remains resilient and retains its shape under heat and pressure. Subsequently, the application of uniform pressure is crucial to facilitate a flawless transfer from the paper to the beanie. Keeping the fabric taut and smooth is equally important; any slackness might result in unwanted wrinkles or distortions.

Precise positioning and alignment of the design are indispensable. This attention to detail guarantees the final product aligns seamlessly with the envisioned design, making the acrylic beanie a perfect canvas for your creative expression!

Tips for Successful Sublimation on Acrylic Beanies

To ensure successful sublimation on acrylic beanies, it is important to use the right heat press and keep a constant temperature, properly place and align the design, and use high-quality dye and paper.

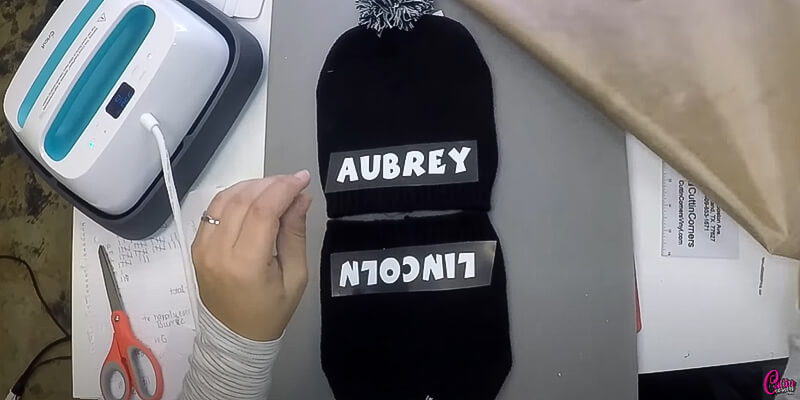

How do you heat press an acrylic beanie?

To transfer a design onto an acrylic beanie using a heat press, begin by preparing your desired design. Flatten the beanie on the heat press as much as possible, using a heat press pillow or a towel inside to create an even surface. Carefully position the design on the beanie, covering it with a Teflon sheet or parchment paper to shield it during pressing.

Proceed to press the design, adhering to the recommended settings—usually around 300°F/149°C for a duration of 10-15 seconds. Apply firm, yet cautious pressure, keeping in mind the heat sensitivity of acrylic. Once pressed, peel away the carrier sheet or transfer paper while it’s still warm and set the beanie aside to cool down before wearing.

It’s essential to consult the manufacturer’s instructions for specific guidelines and perform a test press to ascertain the fabric’s heat tolerance. Following these steps meticulously ensures a successful design transfer, resulting in a personalized acrylic beanie ready for use.

Choosing the right heat press

Ensuring the use of the right heat press is fundamental when sublimating on acrylic beanies. For more information on the equipment needed, check our guide on What Temperature Do You Heat Press A Hat.

Despite having a compelling design along with high-quality inks and paper, utilizing an unsuitable heat press can compromise the outcome.

Selecting the appropriate size and shape to align with your acrylic blank is crucial to prevent excessive pressure or heat during printing. Additionally, it is vital to have proper equipment for successful sublimation, featuring adjustable temperature controls. For those seeking a reliable and versatile option, consider exploring more about the Cricut EasyPress, which offers adjustable temperature controls and even heat distribution, ensuring the production of high-quality, resilient sublimated acrylic beanies.

Lacking the essential tools for printing can lead to subpar image quality, resulting from uneven temperatures. This inadequacy can manifest as product defects such as color bleeding or fading, particularly when the finished products are exposed to UV rays outdoors. By addressing these considerations, one can ensure the production of high-quality, resilient sublimated acrylic beanies.

Maintaining the heat press temperature

Sublimating on acrylic beanies demands precision, particularly regarding temperature settings. Achieving the correct temperature is paramount for a seamless and accurate design transfer. Find the ideal settings with our guide on Heat Transfer Vinyl Temperature and Time.

Straying too low or high from the ideal temperature can result in incomplete transfers, color distortions, and potential damage to the acrylic fabric.

To circumvent such issues, adhering to specific temperature guidelines is crucial. These guidelines may vary based on the brand of acrylic fabric in question. Before diving into full sublimation, it’s prudent to conduct a preliminary test on a smaller fabric area. This test serves as an indicator of the heat press compatibility with the specific acrylic material, ensuring you’re on the right track.

Upon determining and verifying the suitable temperatures for the fabric, consistent monitoring of the heat presses becomes essential throughout the production phase. This vigilant approach helps mitigate potential discrepancies and errors arising from temperature fluctuations, thereby maintaining the integrity of the design and the material.

Remember, the diversity in acrylic fabrics means that one size doesn’t fit all. Each brand may have unique properties, making it essential to adjust the settings accordingly. Integrating this practice helps in fostering a smoother sublimation process, reducing the likelihood of any hiccups along the way.

Proper placement and alignment of the design

Accuracy is paramount when sublimating onto acrylic beanies, as even slight misalignments can become glaringly evident in the final product. To attain precise and desirable outcomes, employing certain techniques is essential. Utilizing heat-resistant tape aids in securing the blank firmly, and mirroring the digital print prior to printing is crucial to ascertain the correct positioning of images and text.

Neglecting to adhere to these recommended steps can lead to outcomes that look unprofessional, which, in turn, can tarnish the reputation of your brand. However, with a diligent approach marked by patience and meticulous attention to detail, you can craft high-quality, customized items that will leave your customers impressed.

Use of high-quality sublimation paper and ink

For professional and polished results when sublimating on acrylic beanies, choosing quality materials is pivotal. Using inferior paper and ink will undermine the design’s clarity and vibrancy, leading to a muted or pixelated appearance.

Select high-grade sublimation ink to ensure the colors radiate vibrantly. Similarly, opting for specialized sublimation paper enhances the sharpness and hue of the design. By investing in premium products, you can avoid common issues such as smudging, fading, or burning that often plague substandard materials.

Equally crucial is the application of correct heat settings tailored to different fabric types. A mismatch in temperature can warp the image transferred to your merchandise. Given the crucial role of these elements in producing aesthetically pleasing outcomes, securing top-tier options is a wise investment. They not only yield remarkable images but also offer durability at a competitive price.

Testing and Adjusting

Executing precise tests and adjustments are crucial phases in sublimating acrylic beanies. Prioritizing heat press temperature tests is fundamental to avoid applying excessive or insufficient heat during design transfer onto the fabric.

The optimal temperatures will differ, contingent on the type of acrylic blanks and predetermined printer settings in the pre-printing phase. After experimenting with various paper variations, it’s crucial to proceed with tests on actual fabric pieces.

Always inspect each piece post-heating, assessing color vibrancy, design payoff, and any potential shrinkage issues. A meticulous examination will ensure that the colors are luminous and the design is transferred flawlessly, maintaining the integrity of the fabric.

Conclusion

Sublimation on acrylic beanies unlocks a multitude of unique design possibilities for crafting personalized headwear. These prints showcase vibrant designs, logos, artwork, and faux gems that retain their brightness even after regular washing and wear.

Acrylic fibers, derived from polyacrylonitrile, serve as an excellent medium for absorbing dyes, making them ideal for various printing processes like sublimation, combustion dyeing, or UV curing. While achieving stunning results with this material might necessitate meticulous attention to temperature and stretch in some instances, the overall outcome is truly fulfilling, catering to a diverse range of markets such as fashion apparel and promotional products.

Decorating acrylic beanies with low heat transfers, such as Siser HTV, elicits the most dazzling effects in custom hats. This technique is optimal for creating unique, personalized styles, making the beanies perfect gifts for corporate events or other special occasions. This method ensures that each beanie stands out, showcasing individuality and catering to the preference for uniqueness in the fashion and promotional sectors.

By harnessing the potential of acrylic fibers and innovative printing techniques, one can create beanies that are not just visually appealing but also durable and versatile. The combination of vibrant colors and intricate designs positions these beanies as prime choices for those seeking to make a fashion statement or a lasting impression.

FAQs

1. Can you sublimate on a hat?

Yes, sublimation on a hat is possible, especially on those made with polyester or polyester-coated materials, as sublimation requires polymers to bind the ink. Ensure the hat is suitable for sublimation, and use a hat press or appropriate heat source to achieve a quality result.

2. At what temperature does acrylic deform?

Acrylic begins to soften around 210°F (100°C) and becomes more pliable around 270°F (132°C). It’s crucial to monitor the temperature when working with acrylic to prevent deformation or damage.

3. Can you heat press acrylic material?

Yes, acrylic material can be heat-pressed, but caution is necessary. Acrylic is sensitive to heat, so use a lower temperature and shorter pressing time compared to other materials. Always conduct a test press to avoid damage.

4. Is acrylic a good material for beanie?

Yes, acrylic is a popular choice for beanies due to its warmth, lightweight, durability, and hypoallergenic properties. It retains shape well, is cost-effective, and offers vibrant, colorfast options. However, individual preferences and needs should guide material choice.