Embroidery vs. Heat Press: Pros, Cons, and Best Uses

Customizing your clothing with eye-catching designs is an excellent way to stand out. Two popular methods to achieve this are embroidery and heat press. But how do you choose between the two? It’s a tough call with several variables at play. In this article, we’ll unpack the differences between embroidery and heat press. We’ll cover the pros and cons of each and offer some tips to help you make an informed decision. So, let’s get started!

Is heat press or embroidery better?

Embroidery is a top choice for corporate attire and sports jerseys, thanks to its high-quality and long-lasting finish. Because the designs are fade-resistant and durable, embroidery is particularly well-suited for uniforms and long-term promotional items. The thread quality ensures that your design stays vibrant, even after multiple washes.

On the flip side, heat pressing is often the go-to method for hats. This is largely due to its quick production time and abundant color options. However, it’s important to note that heat-pressed designs can be less durable over time, potentially cracking or peeling with extended use.

So, when making your choice between embroidery and heat pressing, think about the end goal. Are you aiming for a luxurious, albeit more expensive, stitched design that’s ideal for logos and professional attire? Or would you prefer a budget-friendly option with a broader color palette, better suited for promotional items? Also, don’t forget to weigh practical aspects like durability and care instructions.

Differences Between Embroidery and Heat Press

Embroidery is a sewing technique achieved by stitching designs onto fabric, while heat press involves applying artwork to fabric with the use of heat and pressure. If you’ve ever wondered about the specifics of What Is Embroidery Printing, it’s a method that merges both these techniques to create detailed designs. If you’re considering investing in an embroidery machine, make sure you read about the Pros & Cons: Explained Disadvantages of Machine Embroidery Before Investing to make an informed decision.

Embroidery: stitching designs onto fabric

Embroidery is the art of decorating fabric or other materials using a needle to apply thread or yarn. It may also incorporate other materials like beads, pearls, or sequins. Embroidery has a long history across various cultures and is often associated with high-quality, hand-crafted goods. Want to know more about what influences the Market Demand for Embroidery? Click here.

Process:

- Design Preparation: A design is first created and then digitized into a format that the embroidery machine can understand.

- Stabilization: The fabric is stabilized using a hoop or other method to ensure it remains taut during the stitching process.

- Stitching: The machine (or person, in the case of hand embroidery) uses the needle to apply the thread onto the fabric according to the digitized design.

- Finishing: After stitching, the stabilizer is often torn or cut away, and any loose threads are trimmed.

Features:

- Texture: Embroidery adds a three-dimensional aspect to the design.

- Durability: Because the design is sewn into the fabric, it’s highly durable and resistant to wear and tear.

- Color Vibrancy: The threads used in embroidery are often vivid and maintain their color well over time.

- Versatility: While best suited for certain fabrics, embroidery can be applied to a wide range of items, including clothing, home decor, and accessories.

- Limited Complexity: Extremely detailed or complex designs can be challenging to replicate accurately with embroidery.

Understanding embroidery’s features and limitations can help you decide when it’s the best method for your project. Generally, it’s a great option for work requiring a high-quality, long-lasting finish.

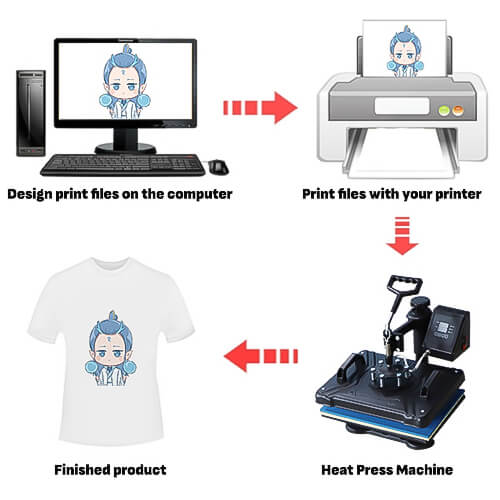

Heat Press: applying designs using heat and pressure

Heat press is a method for transferring designs onto various materials, most commonly fabric, using a combination of heat and pressure. This process involves placing a design on the substrate and then applying heat and pressure through a machine to embed the design into the material. To understand the full scope and capabilities of this method, you might want to read our comprehensive guide on What Is A Heat Press. If you’re specifically interested in making transfers for t-shirts, our guide on How To Make Transfers For T-Shirts offers step-by-step instructions and helpful tips.

Optimizing Heat Transfer Through Effective Heat Press Techniques

Process:

- Design Preparation: The design is initially printed on heat-transfer paper using specialized inks, or pre-made heat-transfer vinyl can be used.

- Placement: The transfer paper or vinyl is placed onto the material where the design will go.

- Application: A heat press machine is used to apply controlled heat and pressure to the design, facilitating the transfer of ink onto the substrate.

- Cooling and Peeling: After heat application, the material is often left to cool for a moment before the transfer paper is peeled away, leaving the design imprinted on the material.

Features:

- Quick Turnaround: Heat press is generally quicker than other methods like screen printing or embroidery, especially for small runs.

- Design Flexibility: Heat press can handle complex and multi-colored designs fairly well, although it’s not as good for very intricate details.

- Versatility: Suitable for a range of materials including fabric, ceramics, and some types of metal.

- Budget-Friendly: This method often has lower setup costs, making it more economical for small batches.

- Limited Durability: Heat-pressed designs may not be as durable as other methods like embroidery or screen printing. They can crack, fade, or peel over time, especially with frequent washing.

Heat press is a convenient and versatile method for applying designs, particularly suited for small batches and complex, multi-colored images. However, it might not be the best choice for projects that require long-term durability. If you’re wondering what size heat press is best for shirts, check out our comprehensive guide.

What is the difference between embroidery and vinyl heat transfer?

Embroidery utilizes thread and needles to create stitched designs on fabric. This method is generally considered to offer a high-quality, textured appearance, making it popular for professional uniforms or luxury items. However, it may be more costly, especially for intricate designs with multiple colors. It’s also most effective on heavier fabrics like cotton, denim, or twill, as lighter or stretchy materials may pucker or distort.

On the other hand, vinyl heat transfer involves cutting a design out of vinyl sheets and then using a heat press to adhere it to the fabric. This technique is generally quicker and less expensive, particularly for small runs. It’s versatile enough to handle intricate details and small text, but it may not be as durable as embroidery over the long term. Vinyl is also more limited in the types of fabric it can be applied to effectively; it may not adhere well to highly textured or stretchy materials.

Both methods have their pros and cons, and the best choice will depend on your specific needs, such as the type of fabric, design complexity, and budget.

Cost and time considerations

Embroidery and heat press are both popular methods for decorating hats but they have different cost and time implications. The table below presents the key considerations:

| Method | Cost | Time |

|---|---|---|

| Embroidery | Embroidery is pricier than heat press printing due to its high quality and detailed finish. Costs rise with design complexity and color count, making it more expensive than other imprinting methods. | Embroidery takes longer, particularly for complex, multi-color designs, but results in a durable and fade-resistant product. |

| Heat Press | Heat press printing is cheaper but its cost varies with design size and color count. While more affordable, it may lack the quality of embroidery. | Heat press is faster and good for last-minute or bulk orders, but the designs may crack or peel, making it less durable than embroidery. |

Given this information, your choice between embroidery and heat press would depend on your budget, time constraints, and the desired look and feel of the final product.

Is it cheaper to embroider or print?

Embroidery tends to cost more due to initial setup fees and the labor-intensive nature of the process. It’s generally better for small, simple, and less colorful designs.

Printing, on the other hand, usually becomes more cost-effective when you’re dealing with larger quantities, multiple colors, or intricate designs. The material you’re printing on can also influence which method is more cost-effective.

So, while embroidery might have a higher initial cost, it could be more durable and give a premium feel. Printing could be more economical, especially for larger runs, but the design might fade over time. The best choice really depends on the specifics of your project.

Durability and longevity

If durability and longevity are your main concerns, embroidery is generally the better choice. Embroidered designs are sewn into the fabric, making them more resistant to wear and tear, and they usually last as long as the garment itself.

In contrast, printed designs can vary in durability. While some high-quality screen prints can also last a long time, many printing methods result in designs that fade, crack, or peel, especially after repeated washing. So, if you’re curious about how long heat-transfer methods can last, it’s worth investigating, Does Heat Transfer Vinyl Last?

So, if you’re looking for something that will endure regular use and washing, embroidery is often a more reliable option.

Applicability on different fabrics and materials

Pros and Cons of Embroidery

Embroidery provides a high-quality, professional look that is long-lasting and resistant to fading. It’s best suited for logos and uniforms, however, it can be limited in terms of color options and time-consuming to produce intricate designs. Curious to find out more? Here’s how embroidery stacks up against other methods in our Embroidery vs Screen Printing article.

Pros of Embroidery:

- Durability: Embroidered designs are generally more durable and can withstand multiple washes without fading or unraveling.

- Premium Look: Embroidery often provides a high-end, professional appearance that is hard to replicate with printing methods.

- Longevity: Because the thread is sewn into the fabric, the design usually lasts as long as the garment itself.

- Texture: Embroidery adds texture and depth to a design, giving it a unique, tactile feel.

- Color Fastness: The colors in embroidery usually stay vibrant longer because the polyester or rayon thread used is more resistant to UV light and washing.

Cons of Embroidery:

- Cost: Embroidery can be more expensive, especially for intricate designs or small quantities. Setup fees for digitizing can also add to the cost.

- Design Limitations: Small text and intricate details can be difficult to render precisely with embroidery.

- Material Restrictions: While embroidery works well on heavier fabrics, it’s not ideal for lightweight or stretchy materials, as the stitching can cause distortion.

- Comfort: The backside of an embroidered design can be scratchy or uncomfortable against the skin, depending on the garment and the quality of the embroidery.

- Weight: Embroidery can add some weight to a garment, which may be undesirable in certain applications like athletic wear.

Pros and Cons of Heat Press

Heat press offers quick and efficient printing, along with a wide variety of colors, making it ideal for event merchandise. However, its designs can be prone to cracking or peeling over time. Learn about the Safe working process of a heat press machine to maximize quality and durability.

Pros of Heat Press:

- Quick Production: Heat pressing is generally faster than other methods like screen printing, especially for small batches.

- Low Cost: For small quantities, a heat press can be more cost-effective since it doesn’t have the same setup fees as methods like screen printing or embroidery.

- Detailed Designs: The method is capable of reproducing intricate designs and a wide range of colors.

- Versatility: Heat press can be used on a variety of materials, including fabric, ceramic, and even metal, making it a versatile choice for different types of projects.

- Low Minimums: Because it’s cost-effective for small runs, you can use a heat press for personalized items or small orders.

Cons of Heat Press:

- Durability: Designs can fade, crack, or peel over time, especially with frequent washing.

- Feel: The design often has a plastic-like texture, which some people may find less comfortable than other methods.

- Heat Sensitivity: The high temperatures used can be problematic for certain materials, potentially causing them to melt or deform. If you’re curious about alternatives that offer a blend of durability and design flexibility, you might be interested in learning about What Is A Screen Print Transfer.

- Limited Size: The size of the design can be limited by the size of the heat press plate, which might not be suitable for large-scale prints.

- Color Limitations: While it can reproduce many colors, the colors might not be as vibrant or durable as those in embroidered or screen-printed designs.

Choosing Between Embroidery and Heat Press

Choosing between embroidery and heat press involves considering a variety of factors such as the project’s purpose, the material you’re working with, the longevity you desire, and your budget. If you’re still undecided or curious about how these methods compare to screen printing, you might want to read our in-depth guide on Screen Printing Vs Heat Press. Here are some guiding points:

Purpose of Project

- Corporate or Formal Wear: If you’re aiming for a high-end, professional finish, embroidery is generally better suited for corporate or formal attire.

- Casual or Promotional Items: For casual wear, promotional items, or small custom batches, a heat press may be more appropriate due to its lower cost and faster turnaround.

Material

- Heavier Fabrics: Embroidery is often better for heavier, more structured fabrics like denim or twill.

- Lighter or Heat-Sensitive Materials: Heat press works well on lighter fabrics and materials that can lie flat, but be cautious with heat-sensitive materials.

Longevity and Durability

- Long-term Use: If you want the design to last as long as the garment itself, embroidery is usually more durable.

- Short-term Use: For items that don’t need to last a long time, like promotional t-shirts for a single event, heat press is usually sufficient.

Budget

- Higher Budget: If you’re willing to invest more for a premium finish, embroidery is the better choice.

- Tighter Budget: For small batches or if you’re cost-sensitive, the heat press often comes out cheaper, especially since it usually doesn’t have setup fees.

Design Complexity

- Simple, Bold Designs: Embroidery works well for simpler designs where a textured, 3D look is desired.

- Intricate or Multicolored Designs: Heat press can reproduce complex, multicolored designs more easily than embroidery.

Ultimately, the best method will depend on a combination of these factors. Embroidery offers a premium, long-lasting finish but may be cost-prohibitive for some projects. Heat press offers speed and versatility but might fall short in terms of durability and premium feel.

Understand the maintenance (washing and ironing instructions)

Understanding the maintenance requirements of garments with embroidered or heat-pressed designs can help prolong their lifespan. Here’s a quick guide:

Embroidery:

- Washing: Machine washing in cold water on a gentle cycle is usually fine, but it’s a good idea to turn the garment inside out to protect the embroidered design. Avoid using bleach or harsh detergents.

- Drying: Air-dry if possible. If you must use a dryer, use a low heat setting. High heat can cause the embroidery thread to shrink or colors to fade.

- Ironing: If you need to iron, do it from the reverse side of the garment, or place a cloth between the iron and the embroidery to avoid direct contact with the threads.

Heat Press:

- Washing: Turn the garment inside out before washing it in cold water. Avoid using bleach and harsh detergents. Some recommend hand-washing for longer-lasting designs.

- Drying: Air-drying is preferred. If using a dryer, choose a low-heat setting. High heat can cause the design to crack or peel.

- Ironing: Never iron directly on a heat-pressed design. If you need to iron the garment, turn it inside out and use a low heat setting, or place a cloth between the design and the iron.

By following these maintenance instructions, you can extend the life of both embroidered and heat-pressed garments. Generally, embroidered designs are more resilient to washing and wearing, but both types will benefit from gentle care.

Conclusion

Choosing between embroidery and heat pressing for your custom apparel really boils down to your specific needs and goals. If you’re after a polished, professional look that stands the test of time, embroidery is your go-to option. On the other hand, if you need intricate designs with a quicker turnaround, heat pressing is a solid choice.

While heat pressing may not offer the same fade resistance as embroidery, it does have the advantage of being versatile across different fabric types. So, before making your decision, consider a few key factors:

- Intended Use: Are you customizing corporate wear, sports jerseys, or promotional t-shirts?

- Desired Look: What impression do you want to convey through your branded apparel?

- Budget: How much are you willing to invest in the customization?

- Fabric Type: Whether you’re working with sweatshirts or cotton t-shirts, ensure the method you choose is compatible with your fabric.

By taking these aspects into account, you can make a more informed decision that aligns with your customization objectives, all without sacrificing quality.

Frequently asked questions

1. What are the pros and cons of embroidery machine?

- Pros:

– High-Quality Output: Embroidery machines deliver high-quality and professional-looking designs.

– Durability: Embroidered designs are durable and long-lasting.

– Speed: These machines can complete complex designs more quickly than hand embroidery.

- Cons:

– High Initial Cost: Embroidery machines can be expensive to purchase and maintain.

– Complexity: There can be a steep learning curve, particularly for complex machines.

– Limited to Certain Materials: Not all fabrics are suitable for machine embroidery.

2. Which lasts longer, screen printing or embroidery?

- Generally, embroidery tends to last longer than screen printing. The threads used in embroidery are more durable than the ink used in screen printing.

3. Is starting an embroidery business worth it?

- The viability of starting an embroidery business depends on various factors such as location, target market, and business skills. Embroidery services are often in demand for customized apparel, so there is potential for profitability. However, the initial investment in equipment and materials can be high.

4. How long does embroidery last?

- Embroidery can last a very long time, often outlasting the fabric it’s stitched into if high-quality thread is used and the garment is properly cared for.

5. What are the disadvantages of heat press printing?

- Limitations on Materials: Not all fabrics can withstand high heat.

- Durability: Heat-pressed designs may not be as durable as other methods and can fade or peel over time.

- Complexity: While the process itself is simple, achieving high-quality results can require expertise.