Embroidery vs Screen Printing: Analysis for Best Choice

Embroidery and screen printing are top methods for customizing apparel like t-shirts and hats. This article compares their cost, precision, and durability. Would you like to understand the distinctions between them? Let’s delve deeper.

Distinguishing Embroidery and Screen Printing

Embroidery crafts designs by sewing colorful threads onto hats through varying stitches, be it intricate motifs or simple line-based patterns. Both manual and machine methods serve this purpose, contingent upon the preferred style.

Screen printing, on the other hand, leverages transparencies and stencils to imprint artwork onto fabric items, hats being a prime example. Use a squeegee to spread specialized ink across screens for screen printing. This process ensures detailed impressions, especially when the design is intricate.

Embroidery and screen printing are commonly used techniques for personalizing hats. Your decision to opt for one over the other will be influenced by considerations like price, the desired appearance, level of detail, and longevity.

If you’re looking into different personalization techniques, consider comparing Screen Printing and Heat Press to see which suits your needs best.

Choosing Between Embroidery and Screen Printing

When customizing clothing, think about the garment’s use, fabric type, your budget, and the specific design you’re aiming for.

Is screen printing or embroidery better?

When picking between screen printing and embroidery for clothing or promotional pieces, your personal needs and tastes play a big role.

Screen printing, which uses ink, is great for detailed designs and vibrant colors. It’s especially suitable for big logos on things like T-shirts. In contrast, embroidery involves stitching, creating a raised, professional finish suitable for smaller logos on polos or hats.

Screen-printed items might fade with frequent washing, but are generally more affordable, especially in bulk. Embroidered designs are durable and versatile but can be pricier, especially with complex designs.

In terms of production, screen printing is faster for large orders, while embroidery takes longer, especially for intricate patterns.

In summary, if you seek a vibrant design for casual garments, consider screen printing. For a refined, professional touch, embroidery might be more appropriate. Always weigh factors like budget, design specifics, and the garment’s purpose before deciding.

Consider the garment’s usage

Deciding on embroidery or screen printing for hat decoration can be challenging. The garment’s nature and purpose play pivotal roles in this choice.

Take baseball caps, for instance. Their flat surfaces make them perfect for both methods. Yet, many lean towards embroidery for its lasting durability, especially when showcasing a cherished logo or design.

Moreover, beanies, with their unique curved surface, are better off with embroidery. This technique effortlessly manages intricate patterns, something screen printing might struggle with.

Consider the garment type

Choosing the right decorative technique for apparel, especially hats, hinges largely on the fabric type. Specifically, embroidery tends to work well on heavier garments like jackets or hoodies. Why? Because embroidery adds a touch of weight, giving the item a premium, textured feel.

Conversely, screen printing shines on lighter fabrics, making it ideal for t-shirts. If you’re weighing embroidery against screen printing for hats, consider multiple factors. Think about your hat’s intended use, sure, but also ponder color schemes and textures. These elements can elevate your design, making it truly unique.

Your choice between embroidery and screen printing will impact not just the cost, but also your design’s overall look and durability. For example, embroidery provides a touchable, textured look that’s durable for everyday use, which is ideal for things like caps.

Finally, let’s talk about your end goal. If you’re going for a professional or formal vibe, embroidery is often the go-to for logos. However, for more casual, promotional apparel, designers typically favor screen printing due to its cost-effectiveness.

Budget considerations

When deciding on embroidery or screen printing for hat personalization, consider your budget as a primary factor. Embroidery often comes with a higher price tag due to its labor-intensive approach. Although the upfront costs can be steep, the superior detail and quality might justify the extra expense.

Don’t forget about other potential costs like hoop or backing replacements and digitizing fees. These extra charges can gradually increase your project’s total price. However, you might catch a financial break on bulk orders, but always confirm discount possibilities with your supplier first.

On the flip side, screen printing generally has a more budget-friendly profile. The setup costs for artwork and the materials needed—such as screens and inks—are typically less expensive. Plus, screen printing usually has a faster turnaround time.

That said, be mindful of possible extra costs. If your design is particularly complex, you might incur additional charges for varied positioning or detailed color-mixing processes. Ensure you understand these aspects to gauge the actual expense of your chosen customization approach.

Desired design detail and complexity

When weighing the options of embroidery and screen printing for hat personalization, consider the level of detail and complexity in your design. Embroidery shines when it comes to presenting detailed patterns and fine text, providing a sophisticated and raised finish.

In contrast, screen printing is your go-to for complex designs that require a range of colors. Not only is this method long-lasting, but it’s also cost-effective. If your design features unusual placements like diagonal logos, consider the precision required in embroidery’s stitch count.

The type of garment you’re decorating also matters. For instance, a hoodie might need a larger surface area to fully showcase a logo compared to a knit polo shirt. Therefore, be sure to plan out all the design elements before settling on your personalization method.

Cost and Durability Comparison

Comparing costs and durability is tricky since neither method clearly outshines the other. We’ll compare the initial costs, maintenance expenses, and durability factors like wear and washing effects for both embroidery and screen printing.

Is screen printing cheaper than embroidery?

When deciding between embroidery and screen printing for hat customization, the intricacy and complexity of your design play a significant role. Embroidery is particularly adept at showcasing fine details and tiny lettering, giving a refined and tactile appearance.

In contrast, screen printing is your go-to for complex designs that require a range of colors. Not only is this method long-lasting, but it’s also cost-effective. If your design features unusual placements like diagonal logos, consider the precision required in embroidery’s stitch count.

The type of garment you’re decorating also matters. For instance, a hoodie might need a larger surface area to fully showcase a logo compared to a knit polo shirt. Therefore, be sure to plan out all the design elements before settling on your personalization method.

Initial cost comparisons

Embroidery and screen printing each come with their own initial costs that can greatly influence the final choice for hat decoration. Here is a concise comparison:

| Embroidery | Screen Printing | |

|---|---|---|

| Equipment Cost | Embroidery machines are often pricier than screen printing equipment, with some models costing thousands. | Screen printing equipment is usually cheaper than embroidery machines, with initial costs as low as a few hundred dollars, making it more accessible for small businesses and hobbyists. |

| Design Set-Up Cost | Digitizing embroidery designs can be expensive, but the digitized design can be used indefinitely at no extra cost. | Screen printing set-up is generally cheaper, using stencils and screens, but multi-colored designs need multiple screens, increasing costs. |

| Per Piece Cost | Embroidery costs are determined by stitch count, making complex designs expensive but providing high durability and a professional look. | Screen printing is often cheaper per item, particularly for large orders, but may lack the durability and quality of embroidery |

| Time Investment | Intricate embroidery designs can be time-consuming, potentially raising labor costs. | Once set up, screen printing can quickly produce large volumes, potentially lowering labor costs for big orders. |

Deciding between embroidery and screen printing for hat decoration ultimately depends on your specific requirements, budget constraints, and the desired end result.

Maintenance costs

Maintenance costs for embroidery and screen printing, particularly for hat embroidery, do not appear to have significant differences. It is crucial to take this into account. As a professional in this field, I’ll break down this comparison a little further.

| Embroidery | Screen Printing | |

|---|---|---|

| Upkeep | Regular machine check-ups and needle replacements are essential for maintaining high-quality, continuous embroidery production. | In screen printing, regular cleaning and correct storage of screens are essential to avoid ink clogs that can lower print quality. |

| Materials | Thread costs in embroidery are generally low but can accumulate depending on design complexity and size. | In screen printing, ink is the main recurring expense and can vary with design size and complexity. Generally, inks are pricier than threads. |

| Time and Labor | Complex embroidery designs take longer to complete, potentially increasing hourly labor costs. | Screen printing is faster and more cost-efficient for large quantities, potentially reducing labor costs. |

Determining the precise maintenance costs without delving into your project specifics is challenging. Both embroidery and screen printing come with distinct expenses. The more economical choice between the two often hinges on the unique demands and stipulations of your project.

Which screen printing or embroidery lasts longer?

When it comes to durability and longevity, embroidery generally takes the lead. Embroidered designs last up to five times longer than screen-printed ones because they have more stitches and layers. But Does Screen Printing Last as long? Click the link to learn more.

For hats, good material quality and proper care, such as shaping, can make embroidered designs last longer.

However, screen printing offers distinct benefits. When aiming for special effects such as foil, screen printing is the preferred method. Achieving these effects with embroidery proves challenging.

In the end, your choice depends on your specific needs and goals. Both methods offer impressive durability, but each has its own set of limitations. So, weigh these factors carefully when deciding on the best personalization technique for your hat project.

Durability comparison: wear and tear, washing effects, etc

When it comes to durability, both embroidery and screen printing have their own strengths and weaknesses. Particularly for hat embroidery, durability can be a significant factor to consider.

| Embroidery | Screen Printing | |

|---|---|---|

| Wear and Tear | Embroidery is durable due to its thick, sturdy thread, making it ideal for frequently used hats or those exposed to tough conditions. | Screen printing is less durable than embroidery, with designs prone to fading or cracking over time, especially in high-contact areas of the hat. |

| Washing Effects | Embroidered hats are machine-washable and can withstand high temperatures and intense cycles without fading or fraying. For best results, a gentle cycle is recommended. | For screen-printed hats, mindful washing is key to ensure lasting quality, which can be affected by ink characteristics and cleaning techniques. Typically, washing them in a machine on a delicate cycle with cool water is advisable, though the design might gradually lose its vibrancy |

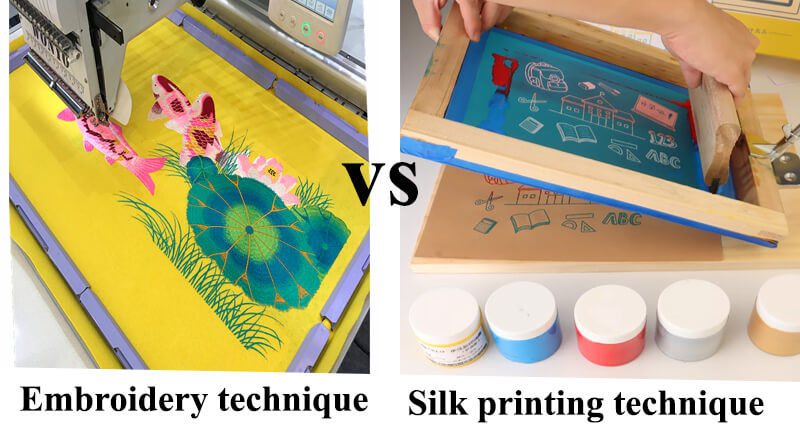

Technical Differences Between Embroidery and Screen Printing

Understanding the techniques behind embroidery and screen printing helps to decide which garment decoration method is more suitable for the task.

What is the difference between silkscreen printing and embroidery?

Embroidery and screen printing are favored techniques for embellishing garments, including hats, with designs and logos. Yet, another approach to consider is the heat press method.. If you’re interested in a comparison, read our Embroidery vs Heat Press: Heat Transfer & Embroidery Analysis.

Embroidery involves intricate stitching, and layering threads like satin, cotton, or rayon to create detailed designs. This method excels in fine detailing, making it perfect for intricate patterns.

On the other hand, screen printing employs stencils and ink to decorate fabric. An automated printer can transfer the design in one go. While some basic shading is possible with contrasting inks, the technique is generally less detailed than embroidery. As a result, screen printing is often a better fit for larger, less intricate logos.

In terms of cost, embroidery tends to be pricier. However, many consider the extra expense worthwhile for the added durability it offers, which often influences customer choices when buying hats. So, depending on your priorities—be it detail, cost, or durability—each method has its own merits and limitations.

How each method works

- In screen printing, we create a stencil to block off areas where ink shouldn’t go. Mount the stencil onto a mesh layer, and then fix it onto a frame. Apply ink over the mesh, and place paper on the surface to ensure even ink distribution. The mesh allows ink to pass only through the design areas, transferring the desired pattern onto the fabric.

- In embroidery, a distinct technique, artisans stitch threads directly into the fabric. The process begins when designers craft a design in specialized software and then load it into an embroidery machine. This machine has many needles and follows detailed instructions to stitch designs into fabric, making detailed patterns possible. To understand how this technique contrasts with traditional printing methods, refer to our guide titled What Is Embroidery Printing.

- Embroidery often excels in both professional and casual settings due to its greater detail and softer feel. However, it usually comes with higher setup costs and thus a steeper price point.

- In contrast, screen printing is generally more efficient for covering large spaces with a design. It’s less labor-intensive than embroidery but offers less detail due to the limitations of the ink and stencil.

When choosing between the two, evaluate what’s paramount for your endeavor: intricacy, budget, or spanning vast spaces. Both techniques come with their distinct pros and cons, so make a judicious selection tailored to your unique requirements.

Materials used in each method

Embroidery utilizes a needle and thread to craft detailed designs on textiles. For optimal outcomes, particular threads and suitable fabrics are essential. The end result offers a raised, dimensional appearance that brings depth to the piece.

On the other hand, screen printing employs mesh stencils and inks to imprint designs onto diverse materials, ranging from textiles to wood and metal. In this technique, specialists push inks, which could be water-based or plastisol, through a stencil directly onto the desired surface. These inks are subsequently heat-treated to ensure they remain smear-free and vibrant.

A third option is DTG (Direct To Garment) printing. This modern technique uses pigment-based inks that bond directly with fabric fibers, resulting in durable, long-lasting prints. To learn more about this method, check out our Direct-To-Garment Printing: A Quick Guide. It’s especially useful for garments like T-shirts and hats.

Applications of Embroidery and Screen Printing

Discover the many uses of embroidery and screen printing in home decoration, apparel, craftwork, accessories, and more! Keep reading to learn more.

Suitability for different garments and projects

Embroidery uses a thread for raised designs, adding a luxurious 3D effect. It’s best for polo shirts, hats, and jackets due to its professional look and flexibility. While durable and versatile, it may have higher setup costs and isn’t ideal for complex multi-colored designs.

On the other hand, screen printing, especially on T-shirts, is more common. But can you screen print on polo shirts? Please refer to our article for the best answer.

Screen printing employs stencils and ink, suitable for vivid designs. It’s optimal for T-shirts, hoodies, and tote bags. This technique is cost-efficient for bulk orders and produces detailed graphics. However, the designs may fade with time and it doesn’t have the tactile feel of embroidery.

When choosing, consider your budget, design complexity, durability needs, and fabric type. Embroidery is long-lasting and premium, while screen printing is vibrant but may not suit delicate fabrics.

Professional vs. casual wear

Embroidery crafts raised designs on fabrics, adding a tactile touch. Shirts, blouses, and jackets convey formality and association in professional wear. Casual items like caps, denim jackets, and sweatshirts also feature embroidery for style.

Screen printing, utilizing mesh and ink, allows vibrant and intricate designs. You often see this method used on event T-shirts and professional uniforms. Meanwhile, casual items like graphic tees, hoodies, and tote bags use it for a wider range of designs.

When choosing, consider embroidery for its premium feel and durability, especially on curved surfaces. Screen printing, while versatile in design, is best on flat surfaces and might fade sooner.

Artistic implications of each method

Embroidery and screen printing bring unique styles and intricacies to hat designs.

Embroidery shines when it comes to minute details. Its needlework approach allows for complex stitch patterns. This method blends various threads, offering subtle shading and 3D effects like texture or elevation.

In contrast, screen printing suits bolder graphics.

Though it might lack intricate line definition, it compensates with vibrant colors. This is due to layering multiple ink shades atop one another. For instance, hats with bright team logos typically use screen printing. This method excels for larger symbols or imagery.

Advantages and Cons

Embroidery has its own advantages, such as providing a durable and tactile impression that is visible from a distance. On the other hand, screen printing stands out for its ability to present bolder and brighter colors.

Advantages of embroidery

Embroidery offers unbeatable flexibility and value when it comes to hat personalization. Unlike screen printing, it enables intricate designs and logos to truly pop with impressive 3D effects like shading.

This feature ensures your design remains eye-catching even from afar. Plus, its versatile nature means it works well on almost any fabric, hats included.

As a result, you get a hat that not only looks professional but also exudes style.

Cons of embroidery

Embroidery typically carries a steeper price than screen printing. Given this, it may not be the best option for extensive projects.

Moreover, embroidery can struggle to capture detailed designs as effectively as screen printing. The stitches in embroidery add a raised, sophisticated texture to adorned apparel or caps.

On the other hand, achieving perfect color gradients and shades can be trickier with embroidery than with screen printing.

Advantages of screen printing

- Screen printing is a cost-effective method ideal for various garments, even light and fragile ones.

- Embroidery can harm materials like cotton t-shirts due to its use of needles. In contrast, screen printing uses plastisol ink and a mesh stencil, avoiding this issue. This ensures the design transfers smoothly without damaging the fabric.

- This technique allows intricate designs with multiple colors. The printing process applies each color one after the other, unlike embroidery, which applies colors simultaneously.

- Moreover, recent water-based inks enhance the process. They offer vibrant, lasting colors and have low VOC rates. This makes them a safer and eco-friendly alternative to traditional plastisol inks and embroidery threads.

Cons of screen printing

Screen printing, while versatile, presents challenges, especially for intricate artwork with effects like shading. Unlike embroidery, it offers less flexibility for certain fabrics or apparel. Upfront costs can be steeper, particularly for small orders.

Why? Each color demands a unique screen, ramping up the complexity and price. This can be particularly costly for items like hats.

Moreover, screen-printed designs might fade quicker than embroidered ones if not maintained well.

Such decline can disrupt branding consistency, especially if customers have grown fond of a particular logo on their cherished hats.

Detail and Complexity

Embroidery and screen printing both offer a variety of detailed and complex options. Therefore, comparing their processes is crucial to achieve the best results. Read on to explore further.

Detail rendering in embroidery vs. screen printing

Choosing between embroidery and screen printing for detailed hat designs hinges on the desired precision and detail. For detailed imagery on garments, screen printing often outshines embroidery, granting better accuracy.

This is especially true for small text, which can lose clarity when embroidered. Yet, modern digital sewing machines are catching up. They efficiently handle designs with photo-realism and complex color blending, all while saving time.

While screen printing delivers sharp lines and vibrant colors, especially with multicolored designs, it lacks the texture that embroidery brings. Embroidery compensates by adding depth through its interwoven stitches.

Color complexities and blending possibilities

If you’re aiming to personalize your hats, embroidery offers a rich palette for color blending. It’s not just about mixing colors; with the right methods and materials, you can achieve stunning gradient effects on any fabric.

Embroidery excels in crafting complex designs with multiple layers, lines, and textures, outperforming many other printing techniques.

One of embroidery’s unique features is its ability to seamlessly blend colors, adding depth in the process. Experts can render these transitions almost invisible, ensuring the design’s details remain sharp and unaffected.

Environmental and Health Concerns

Diving deep into the health and environmental aspects of screen printing and embroidery offers clearer insights into our choices. Continue reading to discover key considerations to bear in mind before embarking on your project.

Chemicals used in screen printing

Embroidery and apparel industries favor screen printing, but the method often raises environmental concerns. Commonly used solvents, including toluene, isopropyl alcohol, and acetone, can harm both the environment and health if improperly discarded.

Moreover, plastisol ink releases harmful chemicals like phthalates and formaldehyde-based resins during production. The World Health Organization (WHO) even labels these substances as potential carcinogens.

However, there’s hope. Water-based inks, free from lead and heavy metals, serve as a safer alternative for screen printing. It’s crucial for embroiderers to opt for eco-friendly solutions that balance both quality and environmental responsibility.

Eco-friendliness in the production process

When weighing eco-friendliness, embroidery emerges as a greener choice compared to screen printing. Embroidery involves fewer chemicals, and many of the stabilizers used adhere to eco-friendly standards.

Moreover, it’s a less wasteful process. Embroidery throws away minimal materials post-stencil cutting.

By utilizing robust, lightweight threads, embroidered garments consume less water in production. Plus, the method reduces fabric waste. Unlike traditional screen printing, it doesn’t require trimming excess areas around stitched designs.

Conclusion

Several factors influence the choice between embroidery and screen printing for hat decoration. These include the type of material, budget, design intricacy, and garment usage.

Embroidery, with its detailed threadwork, often conveys a higher perceived value. Screen printing, however, might be more budget-friendly depending on the design’s size.

In terms of longevity, embroidered designs typically outlast screen prints. There are also notable technical variances between these techniques, from materials to production methods.

So, when deciding between the two, it’s crucial to consider all relevant aspects: upfront costs, upkeep expenses, durability, and wear resistance. This ensures your choice aligns perfectly with your needs.

FAqs

1. What are the advantages of embroidery over printing?

- Durability: Embroidery, using high-quality threads, can resist frequent washing and everyday wear better than some printing methods.

- Appearance: Embroidered designs, often synonymous with premium quality and professionalism, are a popular choice for company logos and uniforms.

- Texture: The raised nature of embroidery gives a unique tactile element that can enhance a design’s appeal.

- Fade Resistance: Embroidery threads tend to hold their color well, resisting sun and wash-related fading.

- Versatility: Embroidery handles a variety of materials, including those that might challenge traditional printing methods.

2. Is screen printing better quality?

- Color Vibrancy: Screen printing excels in producing vibrant and rich colors, especially beneficial for designs on darker fabrics.

- Economical in Bulk: The per-item cost decreases with volume, making it cost-effective for large orders.

- Flexibility: It’s suitable for a broad range of materials, from textiles to ceramics.

- Detail Clarity: For designs with fine details, screen printing can capture and display these nuances effectively.

3. What’s better: screen printing or sublimation?

- Screen Printing: Renowned for producing bold colors and their flexibility across materials. Especially durable with proper curing.

- Sublimation: Ideal for intricate, full-color designs on light polyester materials. The end result is smooth, with the design becoming part of the fabric. Great for detailed graphics and photographs.

4. Why is screen printing so expensive? Why do screen-printed shirts crack?

- Expense Factors:

– Setup Time: Each color and design demands a unique screen setup.

– Manual Labor: It’s a hands-on process that requires skill.

– Materials: Premium inks and cleaning agents add to the cost.

- Cracking Causes:

– Ink Quality: Lower-tier inks can decline over time.

– Curing Process: If not cured adequately, the ink might not bond properly, leading to cracks.

5. What is the most durable t-shirt printing method?

- Screen Printing: Known to endure repeated washes and wear when cured correctly.

- Sublimation: Embeds the design into the fabric, ensuring no peeling or external wear. Particularly durable on suitable materials.

- DTG: Soft feel, detailed designs, but less durable than screen printing on certain fabrics.